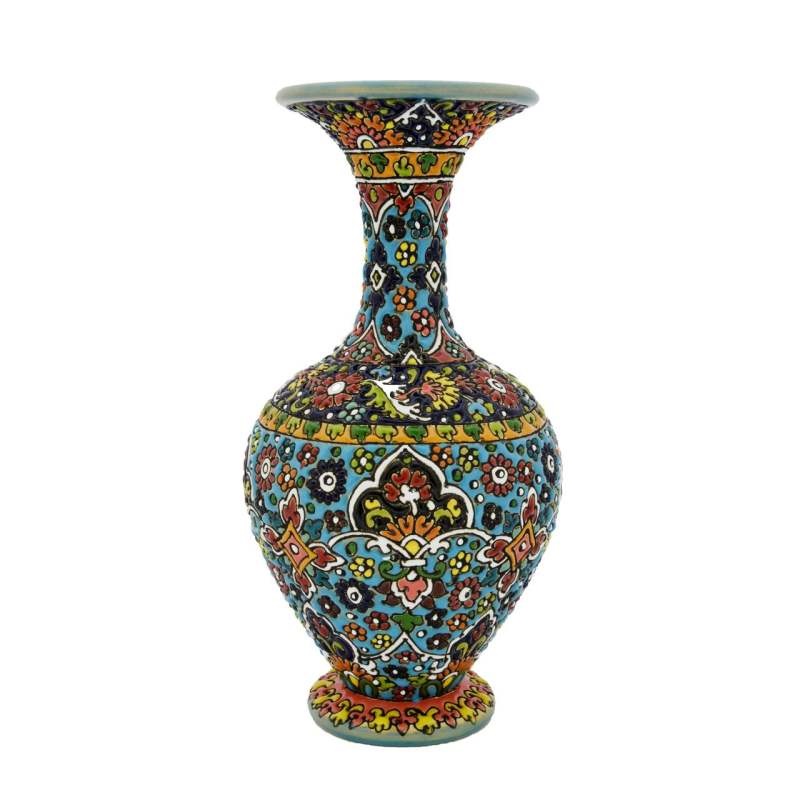

Enamel Work on Pottery: Adding Vibrant Colors to Ceramic Creations

Are you looking to enhance your ceramic creations with vibrant colors? Enamel work on pottery is a fantastic way to add a decorative glaze onto your ceramic work. In this article, we will explore the basics of enamel work, the advantages it offers, and the step-by-step process to achieve stunning results.

What is Enamel Work on Pottery?

Understanding the Basics of Enamel Work

Enamel work on pottery refers to the technique of applying a decorative glaze onto ceramic pieces. The glaze is applied to the surface of your pottery and fired in a kiln to achieve a permanent bond. This process adds vibrant color and a glossy finish to your ceramic creations.

How Does Enamel Work Differ from Other Decorating Techniques?

Enamel work differs from other decorating techniques, such as painting with acrylic paint or using underglazes, as it involves the application of a glaze that fuses with the ceramic surface during firing. This creates a durable and long-lasting decorative finish.

What are the Advantages of Enamel Work?

Enamel work offers several advantages for ceramic artists. First and foremost, it allows for the creation of vibrant colors that can transform a plain ceramic piece into a visually striking work of art. Additionally, the enamel glaze provides a protective layer that makes the pottery food safe and resistant to wear and tear.

Preparing Your Pottery for Enamel Work

Cleaning and Prepping the Ceramic Surface

Prior to applying the enamel glaze, it is crucial to clean and prep the ceramic surface. Start by removing any dust or debris from the pottery using a soft brush or damp cloth. Make sure the surface is completely dry before proceeding.

Choosing the Right Glaze for Enamel Work

When selecting a glaze for enamel work, consider the cone rating, which indicates the firing temperature required for the glaze to mature. Low-fire glazes (cone 06-04) are ideal for beginners, while high-fire glazes (cone 8-10) offer a wider range of colors and effects.

Applying Underglazes for Vibrant Colors

Before applying the enamel glaze, you have the option to use underglazes to add even more vibrant colors to your ceramic piece. Underglazes are ceramic paints that can be applied directly onto the bisque ware, allowing for intricate detailing and shading.

The Enamel Work Process

Applying Enamel Coats to Bisque Ware

Once your ceramic piece is prepped and any underglazes are applied, it’s time to start the enamel work. Using a brush, sponge, or spray bottle, apply thin coats of enamel glaze onto your bisque ware. Ensure even coverage and allow each coat to dry before applying the next.

The Importance of Proper Drying and Firing

After applying the enamel glaze, it is crucial to let the pottery dry completely. This typically takes anywhere from a few hours to a few days, depending on the thickness of the glaze and humidity levels. Once dry, the pottery is ready for firing in a kiln.

Using Different Colors and Techniques

Enamel work allows for limitless creativity by incorporating different colors and techniques. You can experiment with multiple layers of glaze for depth, use oxide washes for highlighting textures, or incorporate lusters for a metallic effect. The possibilities are endless!

Firing and Finishing Touches

Understanding the Firing Process in Enamel Work

The firing process is a crucial step in enamel work. It involves heating the glazed pottery in a kiln to the recommended temperature for the specific type of glaze used. Most glazes require a firing temperature between 1800 and 2200 degrees Fahrenheit.

Applying a Gloss Overglaze for a Smooth Finish

To achieve a smooth and glossy finish on your enamel work, you can apply a gloss overglaze after the initial firing. This additional layer enhances the vibrancy of the colors and provides a protective coating for daily use.

Making Your Enamel Work Food Safe

If you plan to use your enamel-decorated pottery for food or drinks, it is important to ensure that the glaze used is food safe. Look for glazes specifically labeled as food-safe or consult with the manufacturer for confirmation.

Troubleshooting Common Issues

Cracking or Peeling Enamel

If you experience cracking or peeling of enamel, it could be due to factors such as improper thickness of the glaze, poor adhesion, or inadequate firing temperature. Ensure you are following the correct guidelines for glaze application and firing to prevent these issues.

Achieving Consistent Color Results

To achieve consistent color results, it is important to apply the glaze evenly and consistently across the pottery. Avoid applying the glaze too thick or too thin, as this can affect the final color outcome. Additionally, ensure the firing temperature is accurate for the specific glaze used.

Dealing with Undesired Glaze Effects

If you encounter undesired glaze effects, such as pooling or running, consider adjusting the glaze thickness or application technique. Experiment with different brush strokes or application methods to achieve the desired result. Practice and experimentation are key in mastering enamel work.

Conclusion

Enamel work on pottery is an exciting and rewarding technique for adding vibrant colors and a glossy finish to your ceramic creations. By understanding the basics, properly prepping your pottery, mastering the enamel work process, and troubleshooting common issues, you can create stunning pieces of art that showcase your creativity and craftsmanship. So, unleash your imagination and start adding a touch of enamel to your ceramic masterpieces!